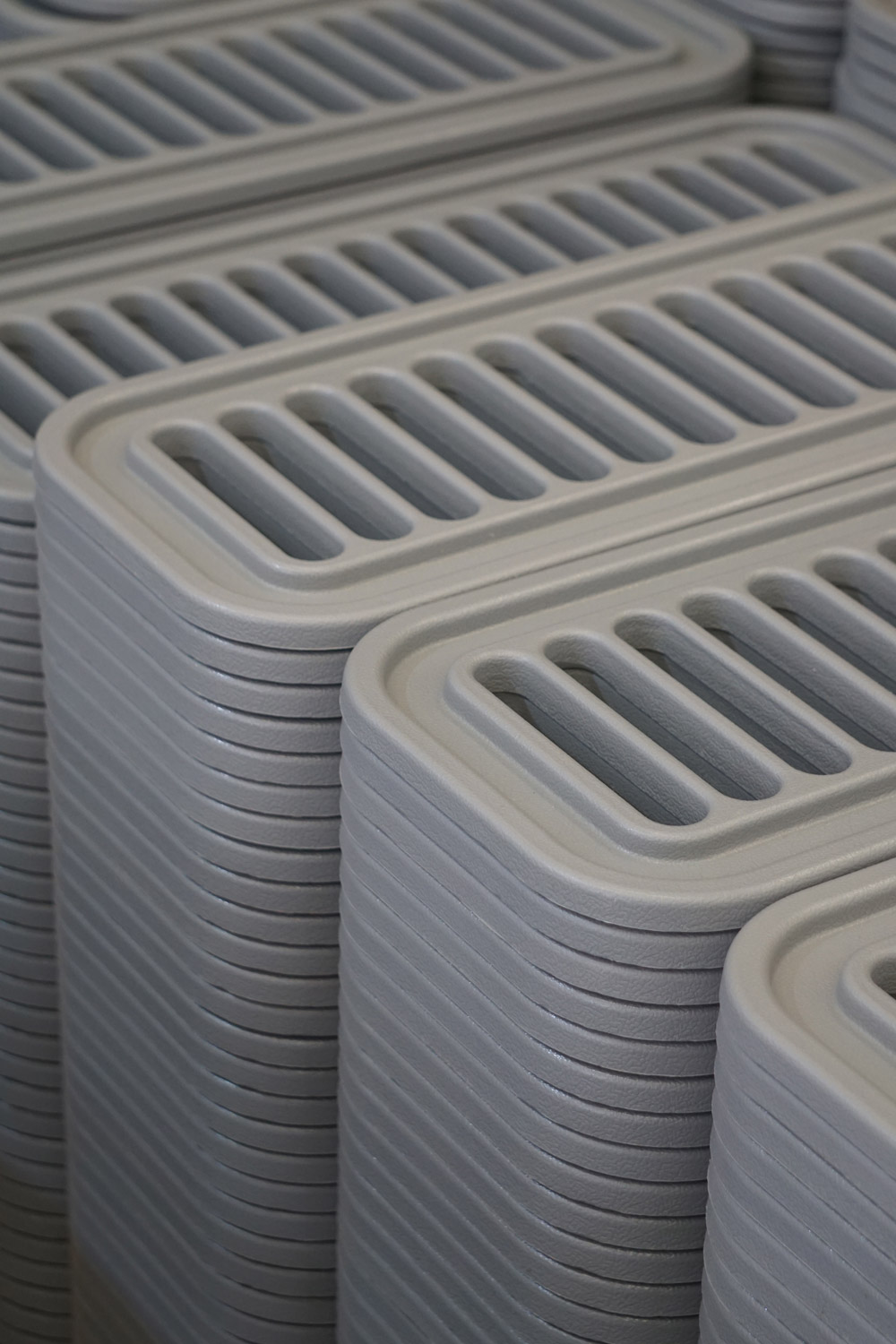

Plastic Injection Production Service

Tesla Otomotiv is a strong production partner in many sectors, primarily in the automotive and industrial fields, with high-quality plastic injection solutions. With advanced injection machines, engineering-supported mold design, and a precision production infrastructure, we offer our customers a competitive edge in both prototyping and high-volume serial production processes.

What is Plastic Injection?

Plastic injection is a production process in which heated thermoplastic materials are injected at high pressure into specially designed metal molds. This method is one of the most commonly used technologies for producing high-precision, durable, and cost-effective plastic parts. Tesla Otomotiv combines this process with advanced automation systems to ensure on-time delivery, minimal waste, and maximum quality.

Materials Used

The thermoplastics used in production are selected based on the intended use and mechanical requirements of the parts. The most commonly preferred materials include:

- Polypropylene (PP): Lightweight and resistant to chemicals

- Acrylonitrile Butadiene Styrene (ABS): High impact resistance and good surface finish

- Polycarbonate (PC): Heat resistant, used in transparent applications

- Nylon (PA): Resistant to friction, ideal for mechanical parts

- Thermoplastic Elastomer (TPE): Flexible and non-slip surfaces

Tesla Otomotiv uses these materials either individually or as a blend to deliver customized solutions tailored to different applications.

Why Tesla Otomotiv?

At Tesla Otomotiv, we consider the production process not just a technical task but an engineering- and partnership-based approach to fully meet our clients’ expectations. With the quality, speed, and flexibility we offer in plastic injection production, we lay the groundwork for long-term collaborations.

- Mold Design: Custom high-precision molds for each project

- Production Capacity: Machines with various tonnage for mass production

- Quality Standards: ISO-compliant production and full quality control

- R&D Support: Prototyping, sample production, and testing services

- Cost Advantage: Material optimization, waste reduction, and on-time delivery

Quality Control and Process Monitoring

Tesla Otomotiv prioritizes quality at every stage of the plastic injection production process. Mold creation, material selection, parameter settings, and final product checks are all conducted in a planned and controlled manner. Our quality control unit visually and dimensionally inspects each part and, if necessary, subjects it to testing procedures to ensure customer satisfaction and product safety.

In addition, digital systems are used for production tracking. All production data, past applications, and client-specific notes are archived and used as references in future projects. This approach supports both sustainability and consistent production quality.

Logistics and Delivery Advantages

In plastic injection production, timely and damage-free delivery is just as important as the production itself. Tesla Otomotiv ensures product safety through special packaging methods and well-planned logistics. Sticking to the delivery schedule, especially in serial production processes, is one of the most important factors in customer satisfaction. Therefore, the production schedule is carefully prepared and managed according to the pre-defined project deadlines.

Looking for a Reliable Plastic Injection Production Partner?

From mold design to mass production, we’re with you at every stage for durable, precise, and aesthetic plastic components. Contact us today to get a customized quote for your project.

Contact Us