Product Description

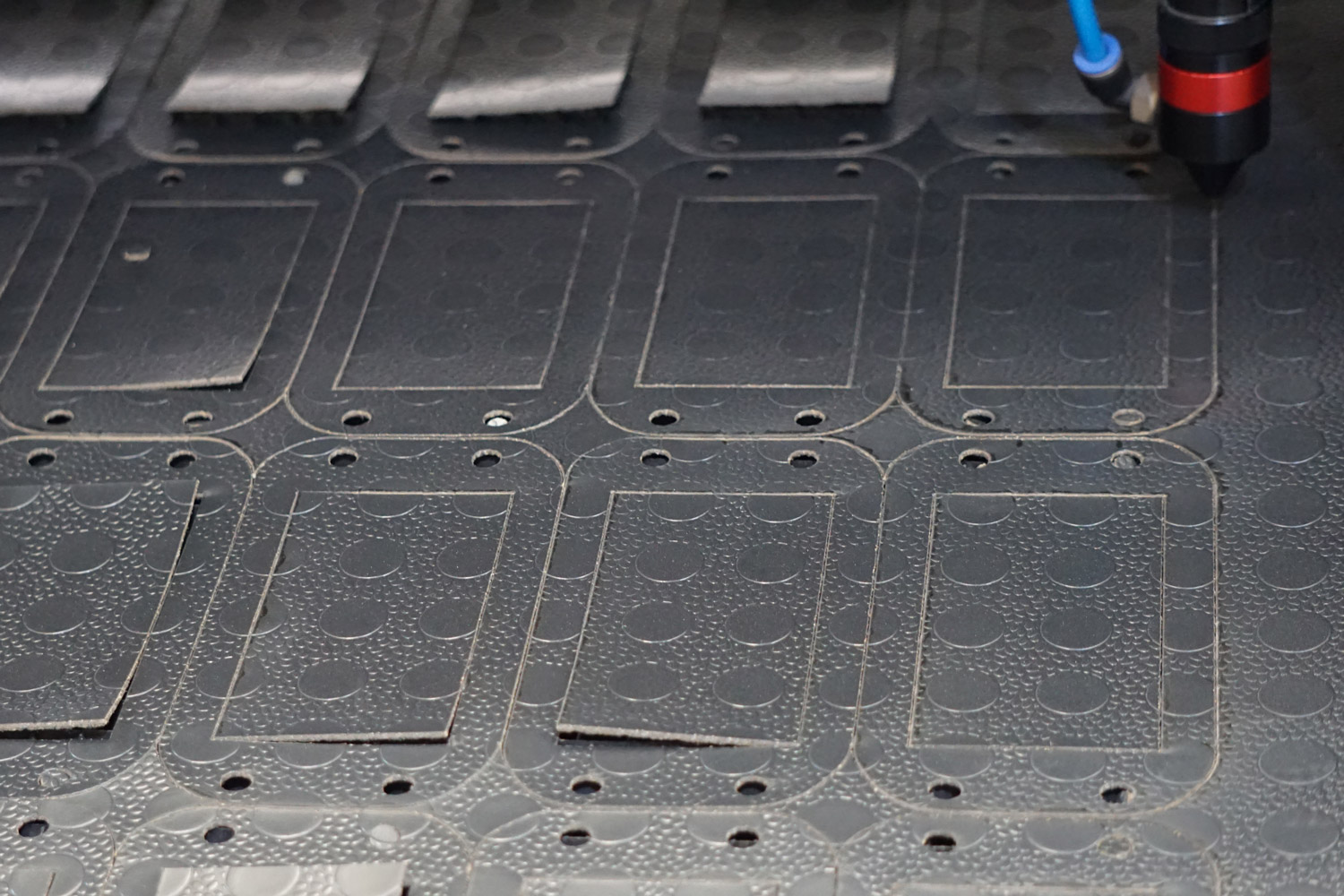

Tesla Otomotiv adds value to the industry with its advanced production infrastructure and high-precision laser CNC cutting machines, enabling precise processing of metal, fabric, and technical materials. Parts required in various sectors such as automotive, defense, textile, and industrial design are cut with millimetric precision and produced to the highest quality standards.

Laser CNC cutting is a cutting method that combines laser technology with computer-controlled (CNC – Computer Numerical Control) machines. The laser beam applies high heat and intensity to the material, melting or vaporizing the surface. This process ensures extremely sharp and smooth cutting lines. Tesla Otomotiv uses this technology to cut mass production parts quickly and flawlessly.

Applicable Materials

Tesla Otomotiv's laser CNC cutting solutions deliver highly effective results on the following materials:

- Stainless steel

- Aluminum

- Fabric and technical textiles

- Plastic sheets

- Composite materials

Thanks to our high-powered laser equipment, both thick and thin materials can be cut with precision. This allows us to offer customized solutions tailored to customer needs.

All laser CNC cutting processes are planned according to customer requirements and go through quality control stages before delivery. This ensures that every product you receive is functional, flawless, and ready for use.

Quality, Flexibility, and Cost Advantage Combined

Laser CNC cutting not only offers precision, but also provides great flexibility and cost advantage in production processes. Compared to traditional cutting methods, it results in significantly less material waste, minimizing scrap rates. This brings both environmental sustainability and cost efficiency. Tesla Otomotiv optimizes materials of different thicknesses and forms according to the specific requirements of each customer project, ensuring the most efficient cutting plan.

The ability to accurately produce even complex geometries allows for more creative and functional solutions at the design stage. In industries like automotive, where error tolerance is minimal, laser CNC cutting technology is indispensable. Being fully aware of this, we operate with systems that ensure dimensional accuracy and surface quality at every stage.

Why Choose Tesla Otomotiv?

All our laser CNC cutting processes are planned in line with customer requirements and go through multiple quality control stages before delivery. This ensures that every product delivered is functional, flawless, and ready for immediate use.

- High precision: Cutting with ±0.1 mm tolerance

- Fast delivery: Production lines suitable for mass manufacturing

- Quality assurance: Every part is individually inspected

- Design compatibility: Production supported by CAD/CAM infrastructure

- Industry experience: Specialized in automotive manufacturing

At Tesla Otomotiv, we continuously improve our laser CNC cutting technology to maximize efficiency, safety, and quality in production—meeting your custom manufacturing needs with excellence.

Areas of Application

Laser CNC cutting is used in the production of a wide range of components within the automotive industry:

- Special mechanism plates for bus and truck curtains

- Frame components for mattress covers

- Support parts for plastic injection molds

- Custom-cut fabric templates for bag and textile production

- Metal support brackets and connection elements

This technology is suitable for both prototyping and high-volume mass production processes.

Need a Production Quote?

If you’d like to learn more about our laser CNC cutting solutions or request a custom quote for your projects, don’t hesitate to contact us.

Contact Us